Izinto zokusetshenziswa zezinto ezihlanganisiwe zifaka i-resin, i-fiber kanye ne-core material, njll.Kunezinketho eziningi, futhi impahla ngayinye inamandla ayo ahlukile, ukuqina, ukuqina kanye nokuzinza kokushisa, futhi izindleko zayo kanye nokuphumayo nakho kuhlukile.

Kodwa-ke, izinto ezihlanganisiwe sezizonke, ukusebenza kwayo kokugcina akuhlobene kuphela ne-resin matrix kanye nemicu (kanye nengqikithi yezinto eziyinhloko esakhiweni sesangweji), kodwa futhi ihlobene eduze nendlela yokuklama kanye nenqubo yokukhiqiza izinto zokwakha esakhiweni. .

Lesi sihloko sizokwethula izindlela zokukhiqiza eziyinhlanganisela ezivame ukusetshenziswa, izici eziyinhloko ezithonya indlela ngayinye kanye nendlela yokukhetha izinto zokusetshenziswa zezinqubo ezahlukene.

Incazelo yendlela:Inqubo yokubumba lapho i-fiber eqoshiwe eqinisiwe kanye nesistimu ye-resin ifafazwa esibunjeni ngesikhathi esifanayo, bese yelapheka ngaphansi kwengcindezi evamile ukuze kwakhiwe umkhiqizo oyinhlanganisela ye-thermosetting.

ukukhethwa kwezinto:

I-resin: ikakhulukazi i-polyester

I-fiber: i-fiber yengilazi eqinile

Izinto eziyinhloko: Akukho, udinga ukuhlanganiswa nama-laminates ngokwehlukana

Inzuzo eyinhloko:

1) Ubuciko bunomlando omude

2) Izindleko eziphansi, i-fiber esheshayo kanye nokubeka i-resin

3) Izindleko zesikhunta eziphansi

Okubi okungalungile:

I-1) Ibhodi laminated kulula ukwakha indawo ecebile ye-resin, futhi isisindo siphakeme kakhulu

I-2) Izintambo eziqoshiwe kuphela ezingasetshenziswa, ezinciphisa kakhulu izakhiwo zemishini yama-laminates

3) Ukuze kube lula ukufafaza, i-resin viscosity idinga ukuba ibe phansi ngokwanele ukuze ilahlekelwe yimishini kanye nezakhiwo ezishisayo zezinto ezihlanganisiwe.

I-4) Okuqukethwe okuphezulu kwe-styrene ku-spray resin kusho izingozi eziphezulu ezingase zibe khona ku-opharetha, futhi i-viscosity ephansi isho ukuthi i-resin kulula ukungena ezingutsheni zokusebenza zabasebenzi futhi ithinte ngokuqondile isikhumba.

I-5) Ukuhlushwa kwe-styrene evuvukale emoyeni kunzima ukuhlangabezana nezidingo zomthetho

uhlelo lokusebenza olujwayelekile:

Uthango olulula, amaphaneli esakhiwo esinomthwalo ophansi njengemizimba yezimoto eziguqulekayo, amaloli amhlophe, obhavu nezikebhe ezincane

Incazelo yendlela:Gcoba ngokwenza imicu nge-resin.Imicu ingaqiniswa ngokuluka, ukuluka, ukuthunga noma ukubopha.Ukubekwa kwezandla kuvame ukwenziwa ngama-rollers noma amabhulashi, bese kuthi i-resin icindezelwe nge-roller yerabha ukuze ingene emicu.Ama-laminates aphulukiswa ngaphansi kwengcindezi evamile.

ukukhethwa kwezinto:

I-resin: akukho mfuneko, i-epoxy, i-polyester, i-polyvinyl ester, i-phenolic resin iyamukeleka

I-Fiber: Ayikho imfuneko, kodwa i-aramid fiber enesisindo esikhudlwana kunzima ukungena ngokubeka izandla.

Izinto ezibalulekile: akukho mfuneko

Inzuzo eyinhloko:

1) Ubuciko bunomlando omude

2) Kulula ukufunda

3) Uma kusetshenziswa i-resin yokwelapha izinga lokushisa ekamelweni, izindleko zokubumba ziphansi

4) Ukukhetha okukhulu kwezinto zokwakha nabahlinzeki

I-5) Okuqukethwe kwe-fiber ephezulu, imicu esetshenzisiwe mide kunenqubo yokufafaza

Okubi okungalungile:

1) Ukuxuba i-resin, okuqukethwe kwe-resin kanye nekhwalithi yama-laminates kuhlobene eduze nekhono labaqhubi, kunzima ukuthola ama-laminates anokuqukethwe okuphansi kwe-resin kanye ne-porosity ephansi.

2) Izingozi zempilo nokuphepha kwe-resin.Lapho isisindo sengqamuzana siphansi se-resin yokubeka isandla, kuba nkulu usongo lwezempilo olungaba khona.Lapho i-viscosity iphansi, kuba lula ukuthi i-resin ingene ezingutsheni zokusebenza zabasebenzi futhi ithinte ngqo isikhumba.

I-3) Uma imishini yokungenisa umoya emihle ingafakiwe, ukuhlushwa kwe-styrene okwenziwa nge-polyester ne-polyvinyl ester emoyeni kunzima ukuhlangabezana nezidingo zomthetho.

I-4) I-viscosity ye-resin yokubeka isandla idinga ukuba phansi kakhulu, ngakho-ke okuqukethwe kwe-styrene noma ezinye izincibilikisi kufanele kube phezulu, ngaleyo ndlela kulahlekelwe izakhiwo zemishini / ezishisayo zezinto ezihlanganisiwe.

Izinhlelo zokusebenza ezijwayelekile:ama-wind turbine blades, izikebhe ezikhiqizwe ngobuningi, amamodeli ezakhiwo

3. Inqubo yesikhwama se-vacuum

Incazelo yendlela:Inqubo yesikhwama se-vacuum iyisandiso senqubo eshiwo ngenhla yokubeka izandla, okungukuthi, ungqimba lwefilimu yepulasitiki luvalwa esikhunjeni ukuze kucishwe i-laminate ebekwe ngesandla, bese kusetshenziswa ingcindezi yomoya ku-laminate ukuze kuzuzwe. umphumela wokukhipha kanye nokuhlanganisa.Ukuthuthukisa ikhwalithi yezinto ezihlanganisiwe.

ukukhethwa kwezinto:

I-resin: ikakhulukazi i-epoxy ne-phenolic resin, i-polyester ne-polyvinyl ester ayifaneleki ngoba iqukethe i-styrene, evuvukala kupompo ye-vacuum.

I-Fiber: Ayikho imfuneko, ngisho nemicu enesisindo esikhulu ingamanziswa ngaphansi kwengcindezi

Izinto ezibalulekile: akukho mfuneko

Inzuzo eyinhloko:

1) Ingafinyelela okuqukethwe kwefayibha ephezulu kunenqubo evamile yokubeka isandla

2) I-porosity iphansi kunenqubo evamile yokubeka izandla

3) Ngaphansi kwesimo sokucindezela okubi, ukugeleza okugcwele kwe-resin kuthuthukisa izinga lokumanzisa imicu.Yiqiniso, ingxenye ye-resin izodonswa yizinto ezisetshenziswayo ze-vacuum

I-4) Impilo Nokuphepha: Inqubo yesikhwama se-vacuum inganciphisa ukukhululwa kwe-volatile ngesikhathi sokwelapha

Okubi okungalungile:

1) Izinqubo ezengeziwe zandisa izindleko zabasebenzi kanye nezinto ezilahlwayo zesikhwama se-vacuum

2) Izidingo eziphakeme zobuchwepheshe zabaqhubi

3) Ukulawulwa kokuhlanganiswa kwe-resin nokuqukethwe kwe-resin kuncike kakhulu ekwazini komsebenzisi

4) Nakuba isikhwama se-vacuum sinciphisa ukukhululwa kwezimo ezishintshashintshayo, usongo lwezempilo ku-opharetha lusephezulu kunalolo lwe-infusion noma inqubo yokulungiselela.

Izinhlelo zokusebenza ezijwayelekile:izikebhe ezinkulu, ezikhawulelwe zesikhathi esisodwa, izingxenye zemoto yomjaho, isibopho sezinto ezibalulekile ekwakhiweni kwemikhumbi

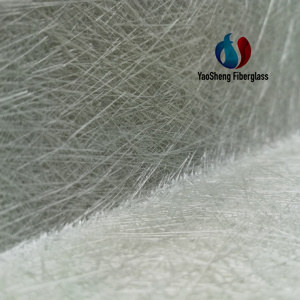

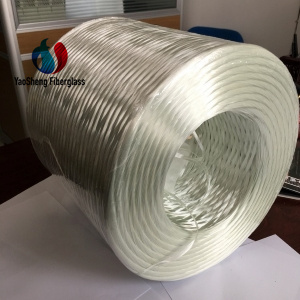

I-Deyang Yaosheng Composite Material Co., Ltd.yinkampani yobungcweti ekhiqiza imikhiqizo ehlukahlukene ye-glass fiber.Le nkampani ikhiqiza ngokuyinhloko i-Fiberglass roving, i-glass fibre eqoshiwe umata we-strand, indwangu yengilazi ye-fibre / indwangu ezulazulayo / indwangu yasolwandle, njll. Sicela ukhululeke ukuxhumana nathi.

Ucingo: +86 15283895376

Whatsapp: +86 15283895376

Email: yaoshengfiberglass@gmail.com

Incazelo yendlela:Inqubo yokusonta isetshenziswa ngokuyisisekelo ukwenza izingxenye zesakhiwo ezingenalutho, eziyindilinga noma eziyisiyingi njengamapayipi namathangi.Ngemuva kokuthi inqwaba ye-fiber ifakwe nge-resin, inxeba ku-mandrel ngezindlela ezihlukahlukene, futhi inqubo ilawulwa umshini wokusonga kanye nesivinini se-mandrel.

ukukhethwa kwezinto:

I-resin: asikho isidingo, njenge-epoxy, i-polyester, i-polyvinyl ester ne-phenolic resin, njll.

I-fiber: akukho mfuneko, sebenzisa ngokuqondile i-fiber bundle yokrebe, asikho isidingo sokuluka noma ukuthunga endwangu ye-fiber

Izinto ezisemqoka: akukho mfuneko, kodwa isikhumba ngokuvamile siwugqinsi oluhlanganisiwe

Inzuzo eyinhloko:

1) Ijubane lokukhiqiza liyashesha, futhi liyindlela eyongayo nenengqondo yokubeka izingqimba

2) Okuqukethwe kwe-resin kungalawulwa ngokulinganisa inani le-resin elithwalwa yi-fiber bundle edlula ithangi le-resin.

3) Nciphisa izindleko zefiber, akukho nqubo yokuluka emaphakathi

I-4) Ukusebenza kwesakhiwo kuhle kakhulu, ngoba izinyanda ze-fiber eziqondile zingabekwa ezindaweni ezihlukahlukene ezithwala imithwalo.

Ukungalungi kahle okukhulu:

1) Le nqubo inqunyelwe ezakhiweni eziyizigodi eziyindilinga

I-2) Imicu akulula ukuthi ihlelwe ngokunembile eduze kwesiqondiso se-axial sengxenye

3) Izindleko zesikhunta se-mandrel wesilisa sezingxenye ezinkulu zesakhiwo ziphakeme kakhulu

I-4) Indawo yangaphandle yesakhiwo ayiyona indawo yokubumba, ngakho-ke ubuhle bumpofu

5) Uma usebenzisa i-low-viscosity resin, kufanele kuqashelwe ukusebenza kwamakhemikhali kanye nokusebenza kwezempilo nokuphepha.

Izinhlelo zokusebenza ezijwayelekile:amathangi okugcina amakhemikhali namapayipi okulethwa, amasilinda, amathangi okuphefumula izicishamlilo

Incazelo yendlela:I-fiber bundle ekhishwe ku-creel iyacwiliswa futhi idluliselwe ku-heater plate, futhi i-resin ifakwa ku-fiber ku-heater plate, futhi okuqukethwe kwe-resin kulawulwa, futhi ekugcineni okokusebenza kuyelapheka kusimo esidingekayo;lo mkhiqizo olashiwe omiswe ngendlela ehleliwe usikwa ngobude obuhlukahlukene.Imicu ingaphinda ifake ipuleti elishisayo ibheke kwezinye izindawo ngaphandle kwamadigri angu-0.

I-Pultrusion iyinqubo yokukhiqiza eqhubekayo, futhi ingxenye enqamulayo yomkhiqizo ngokuvamile inomumo omisiwe, ovumela izinguquko ezincane.Lungisa izinto ezimanzi ngaphambili ezidlula ku-hot plate bese uzisabalalisa esikhunjeni ukuze zelashwe ngokushesha.Nakuba le nqubo ingaqhubeki kahle, ingashintsha umumo we-cross-sectional shape.

ukukhethwa kwezinto:

I-resin: ngokuvamile i-epoxy, i-polyester, i-polyvinyl ester ne-phenolic resin, njll.

I-Fiber: akukho sidingo

Izinto ezibalulekile: azivamile ukusetshenziswa

Inzuzo eyinhloko:

1) Isivinini sokukhiqiza siyashesha, futhi kuyindlela yokonga nenengqondo yokumanzisa futhi ukwelapha izinto

2) Ukulawulwa okunembile kokuqukethwe kwe-resin

3) Nciphisa izindleko zefiber, akukho nqubo yokuluka emaphakathi

4) Ukusebenza okuhle kakhulu kwesakhiwo, ngoba izinyanda zefiber zihlelwe ngendlela eqondile futhi ingxenyenamba yevolumu yefiber iphezulu.

I-5) Indawo ye-fiber infiltration ingavalwa ngokuphelele ukuze kuncishiswe ukukhululwa kwe-volatiles

Okubi okungalungile:

1) Le nqubo ikhawulela umumo we-cross-sectional

I-2) Izindleko zepuleti lokushisa ziphakeme kakhulu

Izinhlelo zokusebenza ezijwayelekile:Imishayo nezinsimbi zezakhiwo zendlu, amabhuloho, izitebhisi nothango

6. I-Resin Transfer Molding (RTM)

Incazelo yendlela:Beka imicu eyomile ekubunjweni okuphansi, sebenzisa ingcindezi kusengaphambili ukuze wenze imicu ifanelane nokuma kwesikhunta ngangokunokwenzeka, futhi uyibophe;bese, lungisa isikhunta esingenhla esikhunjeni esingaphansi ukuze sakhe imbobo, bese ujova i-resin emgodini wesikhunta.

Ngokuvamile kusetshenziswa umjovo we-vacuum assisted resin kanye nokungeniswa kwemicu, okuyinqubo ye-vacuum assisted resin infusion process (VARI).Uma ukufakwa kwe-fiber sekuqediwe, i-valve yesingeniso se-resin iyavalwa futhi inhlanganisela iyelapheka.Umjovo we-resin kanye nokwelashwa kungenziwa ekamelweni lokushisa noma ngaphansi kwezimo ezishisayo.

ukukhethwa kwezinto:

I-resin: ngokuvamile i-epoxy, i-polyester, i-polyvinyl ester ne-phenolic resin, i-bismaleimide resin ingasetshenziswa ekushiseni okuphezulu.

I-Fiber: Ayikho imfuneko.Imicu ethungiwe ifaneleka kakhulu kule nqubo ngoba izikhala ze-fiber bundle zenza kube lula ukudluliswa kwe-resin;kukhona imicu eyenziwe ngokukhethekile ukuze kube lula ukugeleza kwe-resin

Izinto ezisemqoka: Igwebu lezinyosi alifanele, ngoba amangqamuzana ekhekheba lezinyosi azogcwala inhlaka, futhi ukucindezela kuzobangela ukuba igwebu ligoqe.

Inzuzo eyinhloko:

1) Ingxenye ephezulu yevolumu ye-fiber kanye ne-porosity ephansi

2) Njengoba i-resin ivalwe ngokuphelele, inempilo futhi iphephile, nendawo yokusebenza ihlanzekile futhi icocekile.

3) Yehlisa ukusetshenziswa kwabasebenzi

4) Izinhlangothi ezingenhla nezingezansi zengxenye yesakhiwo ziyizikhunta, okulula ukwelashwa okungaphezulu okulandelayo

Ukungalungi kahle okukhulu:

1) Isikhunta esisetshenziswa ndawonye siyabiza, futhi ukuze simelane nokucindezela okukhulu, siyasinda futhi sinzima kakhulu.

2) Kukhawulelwe ekwakhiweni kwezingxenye ezincane

3) Izindawo ezingamanziswanga zijwayele ukuvela, okuholela ekutheni kube nenani elikhulu lezinsalela

Izinhlelo zokusebenza ezijwayelekile:i-space shuttle encane neyinkimbinkimbi kanye nezingxenye zezimoto, izihlalo zesitimela

7. Ezinye izinqubo ze-perfusion - SCRIMP, RIFT, VARTM, njll.

Indlela Incazelo:Beka imicu eyomile ngendlela efanayo nenqubo ye-RTM, bese ubeka indwangu yokukhulula kanye nenethi yokukhipha amanzi.Ngemva kokuqedwa kokuhlelwa, kuvalwe ngokuphelele ngesikhwama se-vacuum, futhi lapho i-vacuum ifinyelela imfuneko ethile, i-resin yethulwa kuso sonke isakhiwo se-layup.Ukusatshalaliswa kwe-resin ku-laminate kufinyelelwa ngokuqondisa ukugeleza kwe-resin ngenetha lomhlahlandlela, futhi ekugcineni imicu eyomile ingena ngokuphelele kusukela phezulu kuya phansi.

ukukhethwa kwezinto:

I-resin: ngokuvamile i-epoxy, i-polyester, i-polyvinyl ester resin

I-Fiber: Noma iyiphi i-fiber evamile.Imicu ethungiwe ifaneleka kangcono kule nqubo njengoba izikhala ze-fiber bundle zisheshisa ukudluliswa kwe-resin

Izinto ezibalulekile: igwebu lezinyosi alisebenzi

Inzuzo eyinhloko:

I-1) Ngokufanayo nenqubo ye-RTM, kodwa uhlangothi olulodwa kuphela oluyisikhunta

I-2) Olunye uhlangothi lwesikhunta yisikhwama se-vacuum, esisindisa kakhulu izindleko zesikhunta futhi sinciphise isidingo sokuba isikhunta simelane nokucindezela.

3) Izingxenye ezinkulu zesakhiwo nazo zingaba nengxenye ephezulu yevolumu ye-fiber kanye ne-porosity ephansi

4) Isikhunta esijwayelekile sokubeka isandla singasetshenziselwa le nqubo ngemva kokuguqulwa

5) Isakhiwo sesemishi singabunjwa ngesikhathi esisodwa

Okubi okungalungile:

I-1) Ngezakhiwo ezinkulu, inqubo iyinkimbinkimbi, futhi ukulungiswa akukwazi ukugwema

I-2) I-viscosity ye-resin kufanele ibe phansi kakhulu, futhi inciphisa izakhiwo zemishini

3) Izindawo ezingamanziswanga zijwayele ukuvela, okuholela ekutheni kube nenani elikhulu lezinsalela

Izinhlelo zokusebenza ezijwayelekile:Ukukhiqizwa kwesivivinyo kwezikebhe ezincane, amaphaneli omzimba wezitimela namaloli, ama-wind turbine blades

8. Prepreg - inqubo ye-autoclave

Incazelo yendlela:Indwangu ye-fiber noma i-fiber ifakwe ngaphambili ngumkhiqizi wezinto ezibonakalayo nge-resin equkethe i-catalyst, futhi indlela yokukhiqiza iyindlela yokushisa ephezulu kanye nokucindezela okuphezulu noma indlela yokuchithwa kwe-solvent.I-catalyst ifihlekile ekushiseni kwekamelo, inika indaba impilo yeshalofu yamasonto noma izinyanga ekamelweni lokushisa;isiqandisi singanweba impilo yaso yeshalofu.

I-prepreg ingaba ngesandla noma umshini ubekwe phezu kwesikhunta, bese umbozwa esikhwameni se-vacuum bese ushisisa ku-120-180 ° C.Ngemuva kokushisa i-resin ingageleza futhi futhi ekugcineni ilaphe.I-autoclave ingasetshenziswa ukufaka ingcindezi eyengeziwe kokubalulekile, ngokuvamile kufika kuma-atmospheres angu-5.

ukukhethwa kwezinto:

I-resin: ngokuvamile i-epoxy, i-polyester, i-phenolic resin, i-resin ekwazi ukumelana nokushisa okuphezulu njenge-polyimide, i-cyanate ester ne-bismaleimide nayo ingasetshenziswa.

I-Fiber: Ayikho imfuneko.I-fiber bundle noma indwangu ye-fiber ingasetshenziswa

Izinto eziyinhloko: akukho mfuneko, kodwa igwebu lidinga ukumelana nokushisa okuphezulu nokucindezela okukhulu

Inzuzo eyinhloko:

I-1) Isilinganiso se-resin ku-ejenti elaphayo kanye nokuqukethwe kwe-resin kusethwa ngokunembile ngumphakeli, kulula kakhulu ukuthola ama-laminates anokuqukethwe okuphezulu kwe-fiber kanye ne-porosity ephansi.

2) Impahla inezici ezinhle kakhulu zezempilo nokuphepha, futhi indawo yokusebenza ihlanzekile, engase yonge izindleko ezizenzakalelayo nezabasebenzi.

3) Izindleko zemicu yempahla engaqondile ziyancishiswa, futhi akukho nqubo ephakathi edingekayo ukuluka imicu endwangu.

4) Inqubo yokukhiqiza idinga i-resin ene-viscosity ephezulu kanye nokumanzisa okuhle, kanye nezakhiwo ezenziwe kahle zemishini nezokushisa.

5) Ukwengezwa kwesikhathi sokusebenza ekamelweni lokushisa kusho ukuthi ukwenziwa ngcono kwesakhiwo kanye nokwakheka kobunjwa obuyinkimbinkimbi nakho kulula ukukufeza.

6) Ukonga okungaba khona ezindlekweni ezishintshayo nezabasebenzi

Okubi okungalungile:

I-1) Izindleko zezinto ziyakhuphuka, kodwa azinakugwenywa ukuze kuhlangatshezwane nezidingo zesicelo

I-2) I-autoclave iyadingeka ukuqedela ukuphulukiswa, okunezindleko eziphezulu, isikhathi eside sokusebenza kanye nemikhawulo yosayizi

I-3) Isikhunta sidinga ukumelana nokushisa kwenqubo ephezulu, futhi izinto eziyinhloko zinezidingo ezifanayo

4) Ezingxenyeni eziwugqinsi, i-pre-vacuum iyadingeka lapho ubeka ama-prepregs ukuze kuqedwe amabhamuza omoya we-interlayer

Izinhlelo zokusebenza ezijwayelekile:izingxenye zesakhiwo somkhumbi-mkhathi (njengamaphiko nemisila), izimoto zomjaho i-F1

9. Prepreg - inqubo engeyona i-autoclave

Incazelo yendlela:Ukushisa okuphansi kokuphulukisa inqubo yokukhiqiza i-prepreg kufana ncamashi ne-autoclave prepreg, umehluko wukuthi izakhiwo zamakhemikhali ze-resin zivumela ukuthi zelashwe ku-60-120 ° C.

Ukwelapha izinga lokushisa eliphansi elingu-60 ° C, isikhathi sokusebenza sezinto ezibonakalayo yisonto elilodwa kuphela;kuma-catalyst aphezulu (>80 ° C), isikhathi sokusebenza singafinyelela ezinyangeni ezimbalwa.I-fluidity yesistimu ye-resin ivumela ukuphulukiswa kusetshenziswa izikhwama ze-vacuum kuphela, ukugwema ukusetshenziswa kwama-autoclaves.

ukukhethwa kwezinto:

I-resin: Imvamisa kuphela i-epoxy resin

I-Fiber: ayikho imfuneko, efana ne-prepreg yendabuko

Izinto eziyinhloko: akukho mfuneko, kodwa ukunakwa okukhethekile kufanele kukhokhwe lapho kusetshenziswa igwebu elijwayelekile le-PVC

Inzuzo eyinhloko:

1) Inazo zonke izinzuzo ze-autoclave prepreg yendabuko ((i.))-((vi.))

I-2) I-mold material ishibhile, njengokhuni, ngoba izinga lokushisa lokuphulukisa liphansi

I-3) Inqubo yokukhiqiza yezingxenye ezinkulu zesakhiwo yenziwe lula, idinga kuphela ukucindezela isikhwama se-vacuum, ukujikeleza umoya oshisayo kuhhavini noma uhlelo lokushisa komoya oshisayo wesikhunta uqobo ukuze uhlangabezane nezidingo zokwelapha.

I-4) Izinto ezivamile ze-foam nazo zingasetshenziswa, futhi inqubo ivuthwe kakhulu

5) Uma kuqhathaniswa ne-autoclave, ukusetshenziswa kwamandla kuphansi

I-6) Ubuchwepheshe obuthuthukisiwe buqinisekisa ukunemba okuhle kwe-dimensional kanye nokuphindaphinda

Okubi okungalungile:

1) Izindleko zezinto zisaphakeme kunefayibha eyomile, nakuba izindleko ze-resin ziphansi kune-aerospace prepreg

2) Isikhunta sidinga ukumelana nezinga lokushisa eliphakeme kunenqubo yokufaka (80-140°C)

Izinhlelo zokusebenza ezijwayelekile:ama-wind turbine blades asebenza kahle kakhulu, izikebhe ezinkulu zomjaho nezikebhe, indiza yokuhlenga, izingxenye zesitimela

10. Inqubo ye-non-autoclave ye-semi-preg SPRINT/i-beam prepreg SparPreg

Incazelo yendlela:Kunzima ukukhipha amabhamuza omoya phakathi kwezendlalelo noma izendlalelo ezigqagqene phakathi nenqubo yokwelapha lapho usebenzisa i-prepreg ezakhiweni ezijiyile (>3mm).Ukuze kunqotshwe lobu bunzima, ukukhishwa kwe-vacuum yangaphambili kwethulwa enqubweni yokubeka izingqimba, kodwa Kwandise ngokuphawulekayo isikhathi senqubo.

Eminyakeni yamuva nje, i-Gurit yethule uchungechunge lwemikhiqizo ethuthukisiwe ye-prepreg enobuchwepheshe obunelungelo lobunikazi, okuvumela ukukhiqizwa kwekhwalithi ephezulu (i-porosity ephansi) ama-laminates amakhulu ukuze aqedelwe ngesinyathelo esisodwa.I-semi-preg SPRINT yenziwe ngezingqimba ezimbili ze-fiber sandwiching ungqimba lwesakhiwo sesemishi yefilimu ye-resin.Ngemuva kokuthi izinto zibekwe esibunjeni, ipompo ye-vacuum ingakhipha ngokuphelele umoya kuyo ngaphambi kokuba i-resin ishise futhi ithambe futhi icwilise i-fiber.kuqinisiwe.

I-Beam prepreg SparPreg iyi-prepreg ethuthukisiwe okuthi, lapho yelashwe ngaphansi kwe-vacuum, ingasusa kalula amabhamuza omoya ezintweni eziboshwe ngamaply amabili.

ukukhethwa kwezinto:

I-resin: ikakhulukazi i-epoxy resin, amanye ama-resin ayatholakala

I-Fiber: akukho sidingo

Izinto eziyinhloko: iningi, kodwa ukunakwa okukhethekile kufanele kukhokhwe ekushiseni okuphezulu lapho kusetshenziswa igwebu le-PVC elijwayelekile

Inzuzo eyinhloko:

1) Ezingxenyeni eziwugqinsi (100mm), ingxenyenamba yevolumu ephezulu ye-fiber kanye ne-porosity ephansi isengatholakala ngokunembile.

2) Isimo sokuqala sesistimu ye-resin siqinile, futhi ukusebenza kuhle kakhulu ngemva kokuphulukiswa kwezinga lokushisa eliphezulu

3) Vumela ukusetshenziswa kwendwangu yefayibha enesisindo esiphansi enezindleko eziphansi (efana no-1600 g/m2), ukhuphule isivinini sokubeka, futhi wonge izindleko zokukhiqiza.

4) Inqubo ithuthuke kakhulu, ukusebenza kulula futhi okuqukethwe kwe-resin kulawulwa ngokunembile

Okubi okungalungile:

1) Izindleko zezinto zisaphakeme kunefayibha eyomile, nakuba izindleko ze-resin ziphansi kune-aerospace prepreg

2) Isikhunta sidinga ukumelana nezinga lokushisa eliphakeme kunenqubo yokufaka (80-140°C)

Izinhlelo zokusebenza ezijwayelekile:ama-wind turbine blades asebenza kahle kakhulu, izikebhe ezinkulu zomjaho nezikebhe, izindiza zokuhlenga

Isikhathi sokuthumela: Dec-13-2022